Publication: Commercial Construction & Renovation, December 18, 2025

Drones provide excellent aerial video and images of construction projects, but their applications far surpass marketing purposes. Poettker Construction launched its drone program in 2024 to support preconstruction, safety, quality, operations and communication in addition to marketing efforts.

“Keeping at the forefront of industry trends is imperative to business growth and meeting customer expectations,” says Ryan Poettker, President of Poettker Construction. “But we don’t adopt new technology simply because it’s trendy. We built a successful drone program because of its wide applications and numerous benefits across our operations.”

Preconstruction

Drone technology can provide benefits even before boots hit the dirt. With drones, Poettker Construction can survey potential project sites or examine prospective buildings for a renovation project. Drones can evaluate the grade of the site and obstacles to construction.

Drone technology can provide benefits even before boots hit the dirt. With drones, Poettker Construction can survey potential project sites or examine prospective buildings for a renovation project. Drones can evaluate the grade of the site and obstacles to construction.

For renovation projects, drones can ascertain existing roof conditions, building envelope tightness, quality of exterior building materials and site conditions, all within a fraction of the time it would take for a survey by foot.

When the client brings Poettker Construction into the project early enough in the planning process, the team can aid site selection and help the client avoid costly change orders through more precise planning.

For these reasons, drone technology also benefits Poettker Construction in building more accurate bids. Poettker recently bid on a project where the location of the build was identified; however, important property grading details were missing from the project documents.

“The more information we have, the more accurate and detailed we can be in our estimate,” says Ryan Diekemper, VP of Preconstruction at Poettker. “We need to know utility locations, if the site is balanced, if the layout requires retaining walls, and if obstacles necessitate removal. We engaged our drone team to provide this data so we could develop an ideal floor elevation, determine site earthwork needs, and calculate cut and fill.”

The drone readings, enhanced by the aid of geolocation, save the estimating team time as well. “If the Poettker team had to plot the site by hand, it probably would have taken four to eight hours to gather the data in the field and another four to eight hours to plot the data.

“Even after eight to 16 hours of effort, my calculations wouldn’t even come close to the precise measurements provided by the drone,” says Justin Dulle, Lead Estimator at Poettker Construction. “Drone technology enables us to seamlessly transfer the data points to the design team as measurements they can use and integrate into their programs.”

Safety

With Safety as a primary core value, Poettker Construction invests in on-site safety representatives who collaborate with the drone team to maximize protection for the company’s project teams and subcontractor partners.

With Safety as a primary core value, Poettker Construction invests in on-site safety representatives who collaborate with the drone team to maximize protection for the company’s project teams and subcontractor partners.

Drone technology enables Poettker to monitor parts of the project site that are otherwise difficult to inspect or unsafe to access. “Drones are essential for monitoring safety, especially in areas not visible from the ground,” says Peter Ratermann, Senior Project Manager at Construction of the Old Monroe Distilling Co. Wedding & Tasting Venue in Columbia, Illinois. “I frequently check drone footage to verify that roofers adhered to safety protocols for working at heights since it’s difficult to assess from the ground.”

Through a digital interface, Poettker employees can review all the project’s drone footage and images in a single location, including examining all the photos ever captured at a specific location on the project site. Increasing project visibility provides another safeguard for identifying and remedying potential hazards before they become a problem.

Avoiding existing utility lines is a key safety concern for construction projects. Colin Kuhn, Project Manager at the renovation of Alton Mental Health Center’s Willow Building says projects like this that span more than a year will have the painted utility line markings eventually wash away. “We used the drone to record the utility locations so that we can identify their locations even after it rains.”

Quality

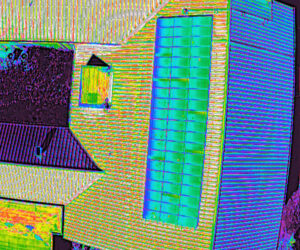

In this thermal image captured by a drone, the yellow spots on the solar panels suggest inconsistent energy performance. Drone technology also benefits Quality, another Core Value of Poettker Construction’s.

In this thermal image captured by a drone, the yellow spots on the solar panels suggest inconsistent energy performance. Drone technology also benefits Quality, another Core Value of Poettker Construction’s.

The architectural plans can be overlaid onto drone footage to ensure the definitive placement of the building on the project site. It can also be used to document product inconsistencies.

The Poettker team noticed that some of the black engineered wood siding was actually a different shade from the rest. It received a bad batch with two different shades of black. The difference was very deceiving and difficult to tell from the ground.

“We used the drones to record the siding progress, which more clearly captured the difference between the two colors and provided a great visual we could send to the manufacturer,” Ratermann says. “Using these photos, we were able to get a representative on site to evaluate, and they agreed to cover the cost of replacement. The drone shots helped significantly to reduce confusion.”

Poettker’s drone fleet includes a model specifically used to create thermal maps. The drone can capture footage for the team to better assess infrastructure deficiencies of renovation projects, such as possible roof leaks or heat loss from insulation gaps, and can even evaluate the effectiveness of solar panels.

“When conducting a solar panel inspection, we’re looking for hotspots,” says Logan Decker, drone operator at Poettker Construction. “Areas that display as hotter than the surrounding space indicate malfunctioning individual grids within the panel not converting the solar energy as efficiently as the rest of the panel. As long as a panel isn’t partly shaded, the entire panel should display the same color.”

Decker recently provided images of problematic solar panels to a client so that they could rectify the issue.

Operations

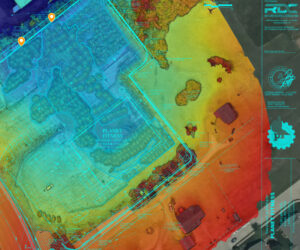

At a Planet Fitness in Missouri, Poettker Construction used a drone to measure the site’s current subgrade elevation, which informed the team how much more dirt was required to achieve the desired grade. With many other projects in the area, the client requested to bring in excess crushed concrete and dirt from their other sites.

At a Planet Fitness in Missouri, Poettker Construction used a drone to measure the site’s current subgrade elevation, which informed the team how much more dirt was required to achieve the desired grade. With many other projects in the area, the client requested to bring in excess crushed concrete and dirt from their other sites.

Drone technology also can be used to measure the height of concrete pads, as well as evaluate stockpile quantities. Another client needed to know how much product they had on site, and Poettker’s drone team assisted—one of the many benefits to hiring a team with advanced resources.

Poettker Construction’s clients, their design teams and other business partners can monitor project progress by accessing drone footage on a digital platform. These images inform the design team when it’s time to visit the site to perform inspections. The inspection findings can then be overlaid onto a site map captured by drones to aid Poettker’s team in remedying any findings.

Community

Poettker’s drone program gives the company an avenue for engaging the local community. The company founded NextGen, a program designed to connect students and teachers to the construction of their facilities and broaden their understanding of the career opportunities available in the construction industry. Drone demonstrations are always well-received by Poettker’s education clients.

Poettker’s drone program gives the company an avenue for engaging the local community. The company founded NextGen, a program designed to connect students and teachers to the construction of their facilities and broaden their understanding of the career opportunities available in the construction industry. Drone demonstrations are always well-received by Poettker’s education clients.

Drone technology improves Poettker Construction’s efficiencies, operations, and bottom line — all of which improve clients’ experience — the ultimate goal of any Poettker Construction investment.